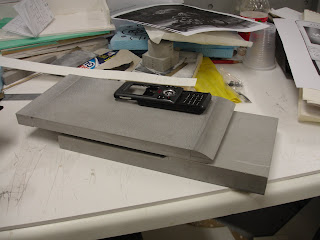

I made my stand from clear acrylic in a simple shape that gives support to the back of the phone at a tilted angle. I will be displaying the model at the New Blades Show, so I have looked into possibly getting a rotating stand for the exhibition, in order to show both sides of the phone equally.

Sunday, 3 May 2009

Putting the phone together

I'm now at a stage where I am putting the different componants of the phone together. I produced a mock screen on photoshop and I've added all the electronics.

Saturday, 2 May 2009

Making the Camera

The camera section at the back of the mobile phone has been one of the most difficult pieces to get right for this model. The finish of the camera is a metallic blue colour. Ideally I wanted to spray a chrome effect base coat and spray over this with a blue tint colour. However the only chrome paint I could find that gives me the effect I need is enamel based from a spray can. As the blue tint I have sourced is a cellulose paint if I spray it directly on top there is a reaction between the two paints which spoils the finish. Not being able however to find a chrome spray with a cellulose base that is reflective enough led me to try producing the two paint coats on separate layers. I therefore vacuum formed the camera section master I had made. On the master I sprayed the chrome effect and on the vacuum form I sprayed the tint. As I used clear styrene to vac form with the reflective layer of chrome can be seen through the blue tinited layer, leaving me with an effect that is close to matching that part of the phone.

Sunday, 5 April 2009

Electrics

As I've detailed in a previous post I have made the phone so that I can use an electroluminescent panel in place of the screen. As this model is an exhibition/display model I think it needs the element of lighting to it to make it more effective and fulfill the purpose it would hypothetically be used in industry for. One of the main issues with using the light panel has been constructing the phone so that there is room for the battery pack that is needed to power the screen. I didn't want to have any wires coming from the phone if I could help it, so I managed to mill out a slot underneath the dialling buttons of the phone, in which the batteries can sit. There are eight AA batteries to hold, which will add a certain amount of weight to the model, however as the basic structure is already quite light, this shouldn't be a problem.

Detailing

Masking

For the back part of the phone half of the outside edge needs to be sprayed in a different colour. For this I needed to mask this line off. I'm using something called fine line tape, which is able to curve with the shape of the phone without gathering, so I can get a neat smooth line.

To get the best results with the tape you need to pull it off once the paint is touch dry. I was really impressed with the result, which produced a neat crisp line.

Spraying...Ahhhhh!

It has come time to spray the phone. By this point I have produced several sample colours and mixed up one that I am happy with and that matches well to the colour of the phone fascia I am using as reference. Before spraying the final cellulose coat I have primed both sides of the phone to a standard where I could not see any marks or dents.

However, when I gave the front face of the phone its first couple of coats of paint, I was not particualrly happy with the result...I had some dry spray around certain sections and there was a quite noticeable blemish on two parts of the phone. One at the top of the phone, and another in the area of where I had slotted in the piece of chemiwood with the walkman logo. This was frustrating as neither of these marks could be seen in the final coat of primer I had applied. The reason being is because the paint I mixed has a satin sheen to it, therefore in certain lights the marks are visible because the surface is not 100% even. To correct this problem I used wet sand paper at a grade of 8oo to take back any raised areas.

These problem areas continued to show up with another couple of coats of cellulose. Continually spraying and then using a very fine sandpaper grade to try and blend the discrepancies, eventually improved the problem, so the marks are a lot less visible than before.

I was recommended to use cellulose stopper paint to try and correct the problem. This acts as a sort of filler to even out the surface, however on further research of this product and due to time constraints I decided I didn't want to risk causing any further problems.

http://www.lrcars.fsnet.co.uk/page15.html Information page on stopper.

Another issue!

I have come to realise that when the CNC machine cut out the walkman logo on the front of the phone, for some reason it cut the shape bigger than it was meant to. This was a problem also for the shadow gap that runs across the back face of the phone. For the shadow gap I simply got some styrene pushed it into the position I wanted it and filled the rest of the gap up to the styrene. Once the car bodyfiller had set I merely pulled the styrene away and the gap had been made smaller with a really neat crisp line. However this method didn't work for the front logo as it's a much more complex shape. Therefore I had to mill out the section along the front face where the logo was, in order to provide a space. In this space I glued in a piece of chemiwood that had the correct logo size lasercut into it. I used chemiwood rather than acrylic to prevent an obvious difference in material that may have showed up when spraying. Chemiwood, like MDF tends to burn in the lasercutter so I used a setting that was as gentle as possible but that still allowed me to cut all the way through the material, which was 4mm deep. This problem has probably lost me a days worth of time.

Outside Strip

The phone has a strip running along the outside edge of the front face. As this strip is a different colour however to the main face it needed to be constructed separately so that it can be painted separately and then glued on afterwards. I decided to use 1mm styrene to create this section. I cut the template out by hand and using double-sided tape to keep it in place I heat bent it around the edge of the phone. I can now take it off the phone again and it will retain its shape ready to be sprayed.

Getting there!

The phone by this point has really started to take shape. I have finished CNCing the main structure and I am at the point where I have re-corrected the mistake I had made when using the CNC machine with the wrong zero point. Now I am using car body filler to fill in any dents or sections with curves. As the chemiwood had a strong grain like surface to it I have been smoothing that out with sandpaper and coating the phone with primer as I go along. I'm finding that chemi-wood creates a nice surface finish through sanding and works well with car body filler.

Separate Componants

With this model I have been working on the main body of the phone, whilst also trying to create smaller componants such as buttons and alike as I go along, so I can make everything fit together well. One of the central pieces of the phone is the disk button at the front. On the w580i part of this is aluminium and the other part is plastic that has been sprayed with a metal effect. I have chosen to use aluminium to create all of it, as I think it will look more effective. Both these pieces will need to have an emblem cut into them and I plan to do this through the CNC machine.

DISK BUTTON:

I lathed the larger section of aluminium and then, to sit within it I lathed a disk of black acylic which chamfers inward. The smaller piece on the right of the picture, which will eventually sit in the centre of the disk on the left, was also lathed from aluminium. I then using a hack-saw and metal file cut from the same piece the cross sections.

CHARGER PORT:

This I created from lasercutting different sections from acrylic and then gluing together. I used a thin sheet of brass to act as the connector sections and sprayed the rest of it black.

CAMERA SECTION and DIALLING BUTTONS:

I made the camera section from a sheet of acrylic, creating the raised part using more acrylic and filling between the two levels with car body filler. The buttons that will be used as the dialling buttons were drawn in the programme Rhino, and then laser cut. I then sanded the edges down by hand to give them a slight radius as is the case with the w580i phone.

LOGO:

This part was made from lasercutting the letters and the piece of acrylic needed to sit the letters onto. I then sprayed the back section black and the letters in a chrome effect paint.

Tuesday, 24 February 2009

Screen

I recieved the light panel that I will use for the screen section of the phone at the end of last week. I ordered it from the company Earlsman. For something so small it gives off an even bright light, however it requires 8 AA batteries to power it. I did want to keep all the electronics within the phone model itself, constructing it in a way that I could simply take the two faces apart from each other in order to access them. I would rather keep it self contained as I wanted the phone to be sat on a clear acrylic base, which I didn't want wires ruining the look of, and I also didn't want any holes in the phone where wires run out from. This may be difficult as the battery holder that is supplied is very thick and clumpy. I will need to mill out a lot of the internal part of the phone in order to make a space large enough for the battery pack to sit in.

http://earlsmann.co.uk/ - The website from where I brought the light panel.

Houston we have a problem...

I discovered that yesterday when I used the CNC machine to cut out certain details on the back of the phone I set the zero point too high on the machine's y axis. This means that everything the CNC cut out has ended up being about 8mm higher on the back phone face than it should be. I have started to rectify this problem by cutting a block of chemiwood at 8mm thick and attaching it to the top of the phone and filling in the space with car body filler. As I have already used the router to radius the edges I will have to re-do this part on the top half of the phone. This problem will set me back a day or so, however as not all projects go according to plan I think it is a good skill to learn to rectify them.

TIP: CNC a piece of material first and then cut out its profile so the zero point doesn't become quite so important.

TIP: CNC a piece of material first and then cut out its profile so the zero point doesn't become quite so important.

CNCing

This week I have managed to get on the CNC machine in order to cut out the pockets for my buttons, logo and screen to slot into. As this is the next biggest step to take in making my blocks of chemiwood look more like a phone I am pleased to have got this process underway, especially as I am halfway through the making time I have on this project. I found using the CNC machine quite straightforward, however the job that I was using it for was quite simple to begin with. I only now need to use the CNC machine in oreder to engrave lines on the aluminium disk button that sits in the centre of the phone.

Sunday, 15 February 2009

Laser Cutting the componants

During this week I have used the laser cutter to create some of the small componants of the phone, such as the logo and buttons. I laser cut them from various thicknesses of acrylic and now I can progress with spraying some of them up to produce them as final pieces that I can separately glue into place when the body of the phone is ready.

Friday, 6 February 2009

Colour Samples

I have been looking at the finish of the phone and trying to plan ahead how I am going to make individual parts of it in advance in order to save time. Today I have been creating colour samples for the metallic blue camera section at the back of the phone.

I created the two samples above from first spraying a base coat of metallic silver cellulose paint. For the more blue sample on the left of the pic I sprayed over the silver with a coat of clear laquer mixed with a small amount of ultramarine blue. This was too blue so for the second sample I tinted the laquer with a small amount of blue and yellow to create a teal colour. To improve the samples I think the base silver colour needs to be more reflective, perhaps a chrome like colour would be better. I will also try to experiment with tint colours. At the moment by adding the opaque blue to the laquer there is not enough transparency to see the silver underneath. My tutor has suggested using a tint blue colour that itself is translucent rather than opaque.

I created the two samples above from first spraying a base coat of metallic silver cellulose paint. For the more blue sample on the left of the pic I sprayed over the silver with a coat of clear laquer mixed with a small amount of ultramarine blue. This was too blue so for the second sample I tinted the laquer with a small amount of blue and yellow to create a teal colour. To improve the samples I think the base silver colour needs to be more reflective, perhaps a chrome like colour would be better. I will also try to experiment with tint colours. At the moment by adding the opaque blue to the laquer there is not enough transparency to see the silver underneath. My tutor has suggested using a tint blue colour that itself is translucent rather than opaque.

Creating Curves!

This week as part of my work on the mobile phone model I have created the radius edges. This involved me using the router tool, which runs along the shape of the work curving the edge. I am feeling happier now with the progress of this project as slowly the two chunks of chemiwood I started off with are beginning to resemble the form of the phone.

Friday, 30 January 2009

Construction underway!

This week I have tried to get to stuck in to making the bulk of the phone. I am making it out of chemiwood, which I'll cut and sand down to the basic shape and once finished I will use the CNC machine to cut out the details on either face of the phone.

A lot of making the back face of the phone has involved me using the mill these last few days, so I am happy I have managed to get a large part of the machining work completed during this week. My next big task is to create the radius edges, which I plan to do using the router.

Wednesday, 21 January 2009

Exhibition Phone - Alchemy Model Makers

I carried out some research today and came across the model making company Alchemy, that made two oversized mobile phones for exhibition pieces. The phones are about 6ft in height and have plasma screens that are linked up to speakers and laptops that are inside them.

As the phone model I am creating would be hypothetically used as a display model maybe in a phone network shop, I like the idea of using an element of lighting in the screen.

As the phone model I am creating would be hypothetically used as a display model maybe in a phone network shop, I like the idea of using an element of lighting in the screen.

Tuesday, 20 January 2009

Rhino working

Having talked to my tutor yesterday I have decided the best way to go about making the phone is to cut out the basic shape in chemiwood and router the edges to create the radius sides. I'd then use the CNC machine to cut out the pockets for the buttons and the shape of the screen etc.

In order to transfer the plans into the CNC machine I have had to draw the phone in the program Rhino as below.

Friday, 16 January 2009

Construction Plan

Possible making methods:

- Draw up plans of the phone to machine cut it using the CNC machine. The drawback of this method is that I don't want to be spending too much time on the computer. I won't be learning many hand skills that are transferable in industry.

- Laser cut different layers of the main phone body, make contours to form the radius edges of the phone. This will mean sanding and filling by hand, which will not be as accurate.

- Milling out the main face of the phone in chemiwood. This will provide me with all the cut outs for the buttons and screen etc and also the radius edges. Can then heat bend over a former to create the sloping aspect of the phone. Advantages of using the mill will mean I can improve on my machining skills and rely on laser cutter for cutting the buttons etc.

Thursday, 15 January 2009

Phone fascia

Wednesday, 7 January 2009

Deciding the scale

Today I made a sketch model of the mobile phone W580i out of blue foam. I have decided to create it at a scale of 3:1, with a working sliding mechanism to it.

Monday, 5 January 2009

Introduction

Subscribe to:

Comments (Atom)